This article is the second part of our Reloading for the 5.56 NATO (Remington .223) series and covers the aspects of powder charging, slug selection, bullet seating, and crimping.

*Reloading ammunition is a skill and an art. We suggest anyone interested in reloading train with a professional first.*

Is Your Brass Prepped and Reading for Reloading?

When we left each other last, everyone was scampering off to do brass prep for their AR or Mini 14 .223 rounds. Hopefully, I gave good enough instructions that everyone has a primed, trimmed, re-sized, de-burred, and cleaned piece of brass which is ready to receive a powder charge and a slug. This is precisely what we will do in this section.

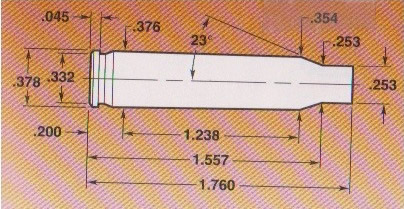

Your prepped brass should look like this:

These dimensions are nominal dimensions and some have a tolerance of almost 0.010 inches! But nonetheless, they are good solid guidelines to work from. Note the trim length on this is NOT 1.750”. That is the length it is recommended to trim to so the shell can “grow” into a nominal length with use.

Powder Selection for Reloading 5.56 NATO (.223 Remington)

Now, let’s talk about powder selection. (This is bound to start an argument.) I like to use common, easy to find, and multi-purpose powders.

I have so many different firearms for so many different purposes, that if I bought different powders for each round I loaded, I’d have a loading bench the size of a tennis court! Remember, in a survival cache, space is at a premium.

I use IMR 4895 for my .223 loads. It is a medium to slow burning powder, and a little dirty, but it has MANY uses and is readily available.

More desirable results can be achieved with other powders such as VIHT N-140, VIHT N-135 and AA2495, but this powder will suffice for our purposes and many others.

Many service rifles have shorter barrels and thus would benefit from faster burning powders. When selecting a powder for load development, barrel length is of paramount importance!

Longer barrels, which generally yield better long range accuracy, afford slower burning powders. The slower burning powder allows for combustion the full length of the barrel. Shorter barrels require faster burning powders. This affords time for the powder to complete its burn the full length of the barrel, yet not waste powder. (Read a 3 foot flame at the muzzle.)

If you have an unusually large muzzle flash, consider a faster burning powder, as you are wasting powder. (The flash is a dead giveaway; combustion is happening OUTSIDE the barrel and thus NOT propelling the bullet inside the barrel.)

Powder Measure and Bullet Weight

Another consideration in powder selection is bullet weight. Powders must be charged into the shell according to bullet weight. An undercharged or overcharged shell is dangerous! One MUST either purchase a load manual (Speer, Hornady, and several others make them commercially available); look them up on the internet (not recommended for reliability); or, consult a ballistics expert.

Sierra has a team on standby at 800-223-8799 Monday thru Friday 8 to 8 and they are DAMN good at load development. I use them frequently and they are FREE!

For example: According to Hornady, a 55 grain slug will max out around 25.1 grains of powder, while a 75 grain slug will max out at 23.3 grains of IMR4895. Same powder, different load. The logic of bigger slug equals more powder is a fatal mistake, this is why we consult ballisticians and manuals.

More powder with a heavier slug will create an over-pressure situation. The .223 is rated at 55,000 CUP (copper units of pressure) maximum. Our load will generate 49,700 CUP and has been verified as safe. I’ll not get into Copper units of pressure in this article, but if you’re really interested in internal ballistics, you can look it up.

After figuring all this out, I have come to the conclusion that 26 grains of IMR 4895 will work beautifully for our project. It should project our slug forward somewhere between 2900 and 3000 feet per second at the muzzle. So, we dial our powder measures in for 26 grains.

I like to verify 3 absolutely accurate throws of EXACTLY 26 grains before I ever start charging shells. While charging, I check the first five and verify the charge weight with our scales, then check every tenth one thereafter.

Feel free to check EVERY one, the results will be rewarding, but it takes time to verify EVERY load. The 26 grains of 4895 will fill our case and this will be a compressed load when we put our slug on top and seat it. The powder measure should be your friend, BECOME FAMILIAR WITH IT!

Slug Selection, Setting, and Keyholing

The final step of completing your loads is setting the slug. Slug selection is critical! Most factory sporting ammo is loaded in 55 grain bullets. This works just dandy for sporting type rifles with a 1:14 twist barrel. What many folks do NOT know is that the service class rifles (read Mini 14, AR 15 etc.) have a much faster rate of twist. (This rate varies from manufacturer to manufacturer between 1:7 and 1:10)

The military switched to the M855 round which is 62 grains, which is longer, heavier, and of a higher ballistic coefficient. It gives better long range accuracy and higher hydrostatic shock values at extended ranges.

Ever hear stories of bullets “tumbling” or “key holing?” This is the explanation for this phenomena: the faster twist works well with the heavier bullet, but since most commercially available .223 ammo is loaded for varmints, they are NOT of substantial enough construction to withstand the high rate of twist.

By the time a bullet leaves the barrel at 3200 feet per second in a 1:7 twist barrel, it is rotating at over 30,000 RPM. It is literally flung apart by centrifugal force, thus, causing the keyholing and tumbling. We can also eliminate this problem by limiting our muzzle velocity (read lighten our loads) to less than 2800 feet per second when only lighter bullets are available.

“But Ed, whatever will we do?” you ask. Fear not, for several bullet manufacturers have thought this out for us! (You didn’t think I was smart enough to figure this out on my own did you?) Speer makes both 62 and 70 grain bullets for the service class. Hornady makes 68 and 75 grain bullets.

My personal favorite, and what I’m loading for here is the Sierra 69 grain hollow point boat tail. Known to Sierra ballisticians as part #1380 HPBT Match King. This little jewel has solved the accuracy riddle in MY AR for me. (Yours may be different.)

Seating the Bullet and Crimping

All that remains to be done is the simple act of seating the bullet and crimping. Most dies do this in one step. Adjusting this can be tricky. The maximum allowable Cartridge Overall Length or C.O.L. for a 5.56 NATO round fired through an automatic rifle is 2.250”.

Too long a length and feed problems will result. We switch from our re-sizing die in our press to our seating die. Then we gently place a slug in the neck of the charged case. After this, it is a simple matter of pulling the lever and measuring the length of the newly formed cartridge!

Too long? Screw the top insert in on the die. Too short? Let the screw out. SIMPLE! Then inspect where the bullet meets the brass, and see if there is a slight tapered crimp there. This is necessary to keep the slug on top of the brass.

Once you get dialed in to a length of 2.250” you’re ready for mass production. As a side note, some handloaders like to apply a little lube to the bullet before seating. I have never found this to be necessary, but feel obliged to include it.

The final step will be to test our loads, record our load data, and make any adjustments to our next batch. Read the third and final article in our reloading series here.

I just read this article, reloading for 5.56 nato -223 remington-part two-tutorial. Why is there no reference to “part one”….?

Greetings Mr. Edwards, I much enjoyed your article on reloading the .223/5.56 round.

I do wish there was some info on preparing the primer pocket of the 5.56 Nato round,i.e. removing the primer crimp,deburring,etc.

Thank you.

R. Brown

Ocala7@gmail.com

It’s been my experience that you get better powder charge uniformity from ball powders. When the powder supply dried up a few years ago 4895 was just as hard to find as WW748 , Ramshot X-Terminator , H332 , BLC2 and Tac.

I use the top of the line Harrell and Redding BR-30 Measures and find their consensty drop to drop to be amazing. I do check from time to time but seldom if ever find any adjustments necessary. In short the use of ball powders speeds the reloading procedure.

It has been my experience that a buyer of an AR15 type rifle should do himself a FAVOR and decide what he wants from it….then pick the brand that has a twist rate suitable to him. I went thru 3 AR’s before being blissfully satisfied with a1 in 7 twist. That handled 68 thru 90gr. projectiles beautifully. (5 shots to .3028 with thoughtless consistentcy).

What charge weights for 5.56 nato cartridges?

Powder: IMR 3031

Benchmark

Projectile: blitzking 55gr

I am having problems with rounds blowing out the back. Primers blowing out and destroying the bolts. Is there a glue for primers and should the length all together be no longer or shorter then 2.250”?